In the field of vacuum technology are prohibited outgassing materials to use, as they offer properties with which it will be difficult to achieve the desired degree of vacuum. Outgassing materials put gaseous molecules freely which main components can contaminate or settle in parts, making them this against the intended purpose, change.

Originally played metals the key role in creating of parts for applications in vacuum technology intended, since they do not outgas given proper treatment. Most polymers contrast outgas. This is an inherent in polymeric materials property, as these consist essentially of chemicals which tend at an appropriate temperature and pressure to vaporize.

One of the properties of PEEK is its low outgassing, even at relatively high temperatures.

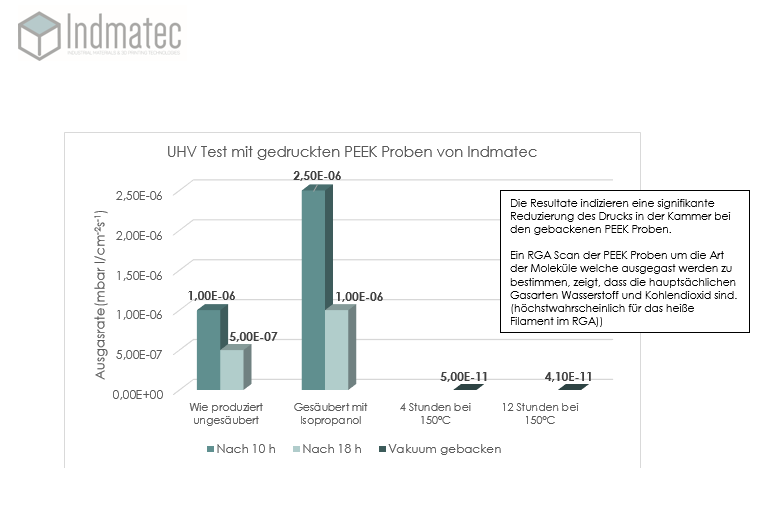

Previous vacuum testing with PEEK parts, made of Indmatecs PEEK filament among uses of Indmatecs 3D printing technology, showed a outgassing rate of

5 × 10 -7 mbar l / cm -2 s -1 after 18 hours in a vacuum. Fact that the PEEK material in his 3D printed state meets the material requirements for high vacuum applications. The printed part PEEK has, after baking for 12 hours at 150 ° C, before the tests under vacuum conditions, an outgassing rate of 4.1 x 10 -11 mbar l / cm -2 s -1 on; a value of exactly falls within the ultra-high vacuum to extreme vacuum range.

The quality of the data together with resistance of PEEK against radiation damage extends the scope of Indmatecs 3D printing technology towards space exploration, are wanted in lightweight materials, which the ongoing requirements for research in space withstand.

PEEK applications for vacuum technology is created with a Indmatec 3D printer

Contact:

Brando Okolo (PhD)

brando.okolo@indmatec.com

recognition:

We thank Mr. Andy Stallwood of Diamond Light source Ltd, vacuum testing

No comments:

Post a Comment