Researchers at ETH Zurich have developed a technology for biological research years ago. This has now been further developed and can produce metal structures in Micro-region

The technology has been licensed by FluidFM spinoff Cytosurge AG and the company’s original technology based on a nanopipette developed.

The technology has been licensed by FluidFM spinoff Cytosurge AG and the company’s original technology based on a nanopipette developed.

The pipette is mounted on a movable leaf spring and can be controlled extremely precisely. By only 300 nm (nanometers) wide opening a copper sulfate solution is applied. By a conductive liquid, and voltage is applied to the pipette tip, there is a chemical reaction. The copper sulfate is made up and he building board made of gold and can be formed by the movement of the pipette

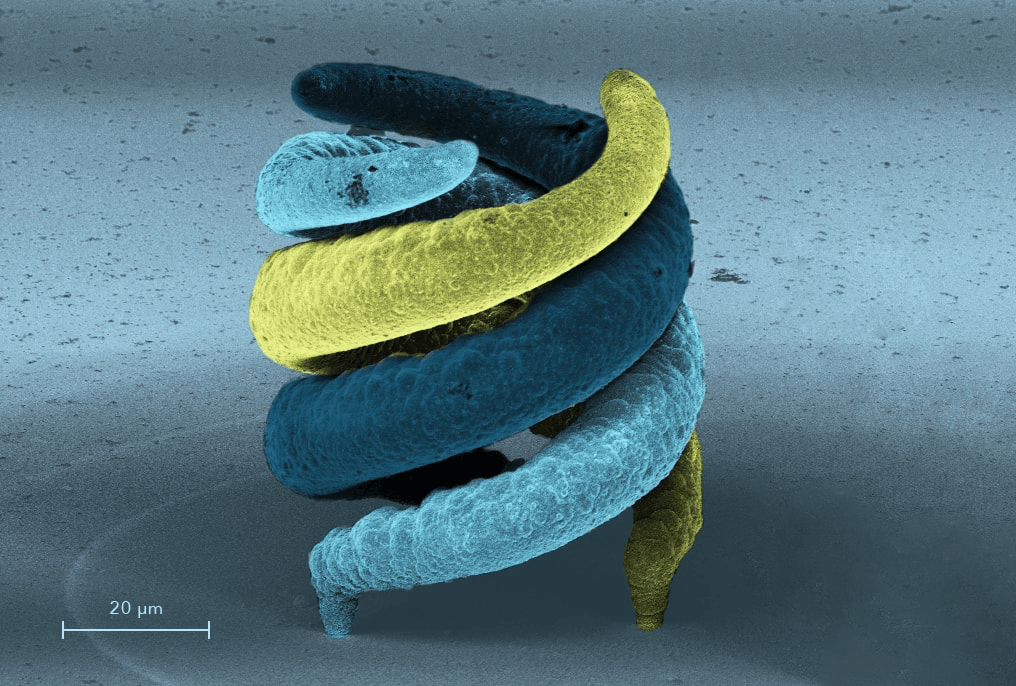

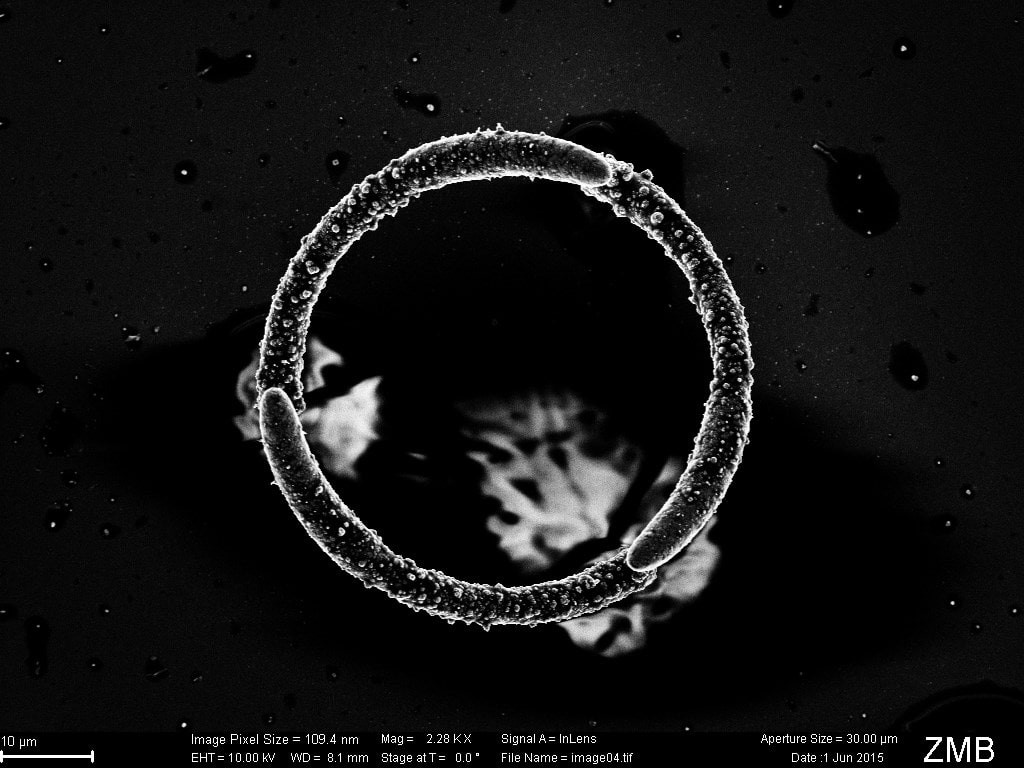

The result is the finest structures in the micrometer range.

Dr. Tomaso Zambelli, Associate Professor and group leader at the Laboratory for biosensors and bioelectronics ETH Zurich:

Not only copper but other metals could be printed thus

And even. for 3D printing of polymers and composite materials are FluidFM® would be suitable.

One of the major advantages of the technology is that the forces can be measured by the pipette tip during operation. Luca Hirt, ETH doctoral student and inventor of the new printing process:

This signal we can use as feedback. In contrast to other systems of our detects which areas of the object have already been printed. This allows you to automate the printing process and scale.

Cytosurge will expand its product portfolio so that the new 3D printing technology interested researchers in industry and universities can be available soon. In addition, an own product category for industrial applications is planned.

Dr. Pascal Behr, co-founder and CEO of Cytosurge, says:

The developed 3D printing method is suitable for uses in a variety of markets. We see first applications present mainly in the watch and semiconductor industry, and medical technology. “Thanks to the latest trends for continuous miniaturization and mass customization and ever shorter development and production cycles comes the new FluidFM® based 3D printing technology precisely to right time. “The new process provides our customers with interesting growth potential and opportunities for increasing efficiency.

Yesterday, in the journal Advanced Materials, the results of research on 3D Micro Printing Technology from Luca Hirt, Stephan Ihle, Zhijan Pan, Livie Dorwling-Carter, Alain Reiser, Jeffrey M. Wheeler, Ralph Spolenak, János Vörös and Zambelli Tomaso published

A spiral structure with FluidFM produced:.

No comments:

Post a Comment